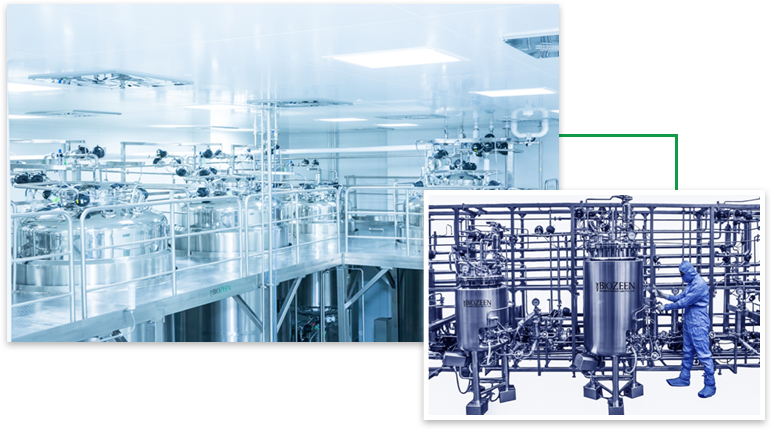

BIOZEEN은 Bioprocess에 필요한 다양한 장비들을 수많은 경험을 바탕으로

직접 제작, 설치하는 고객 맞춤형 솔루션을 제공합니다.

Fermentor

- Minimum space requirement

- Optimized Fermentor design

- Range: 5L – 25000L

- Skid-mounted structure

- Agitator (Top / Bottom mounted)

- Flexibility in the configuration of Fermentor to meet the budgets

- Design compliance to ASME BPE and GAMP 5 guidelines

- Single/double mechanical seal

- Easy access during operation and routine maintenance

- PLC control system

- Safety features to protect the batch in case of any component failure

Bioreactor

- Minimum space requirement

- Optimized Bioreactor design

- Range: 5L – 10000L

- Skid-mounted structure

- Mechanical / Magnetic – low shear Agitator ( Top / Bottom Mounted)

- Gas mixing station

- Flexibility in Bioreactor configuration to meet the budgets

- Design conforms to ASME BPE and GAMP 5 guidelines

- Single/double mechanical seal

- PLC control system

- Safety features to protect the batch in case of any component failure

CIP-SIP System

- Space conserving design

- Skid-mounted

- Integrated mobile or split system

- Flexible range

- Varying configurations

- Minimal maintenance

- Vessel construction in SS 316L

- Requisite instrumentation to accord safety

- PLC control system

- Corrosion-resistant body and trim

- Self-draining design

- The material of construction SS 316L

- Sanitary process connections

Media, Buffer, Process Tanks

- Minimal space requirement

- Easy maintenance

- Easy integration with plant facility

- Flexible range

- Flexible configuration

- Compliance to ASME BPE guidelines,

- ensuring cleanability, drainability and sterilizability

Biokill System

- Flexible range

- Skid-mounted

- Agitator ( Top / Bottom Mounted)

- Configuration to suit space restrictions

- Design conforms to ASME BPE and GAMP 5 guidelines

- Material of construction – SS 304

- Internal finish Ra <= 0.8

- Designed for easy access during operation and routine maintenance

- PLC control system

- 100% redundancy for safety

Filtration System

- Skid mounted, Space conserving, Easy maintenance

- Fixed / Mobile, with or without vessel

- Automated flux measurement to check cleanability

- In-situ sterilizable with or without cassette

- Optimized stabilization time

- Provision for online membrane integrity test

- Cassette holders offered to suit different membrane manufacturers

- Automated trans membrane pressure maintenance

- PLC control system with HMI or SCADA

Automation System

- Seamless automation & Integration of :

- · Multiple unit operations: fermentation, Cleaning in Place, Sterilization in Place, chromatography, etc.

- · Multiple processes: upstream, downstream and fill & finish

- · 3rd party integration: seamless integration of equipment from multiple vendors for multiple unit operations

- Retrofit

- Upgradation of systems